Industrial Automation Systems

Precision Feeding Systems for Modern Manufacturing

Custom vibratory bowl feeders and automatic feeding systems engineered for stability, accuracy, and long-term reliability.

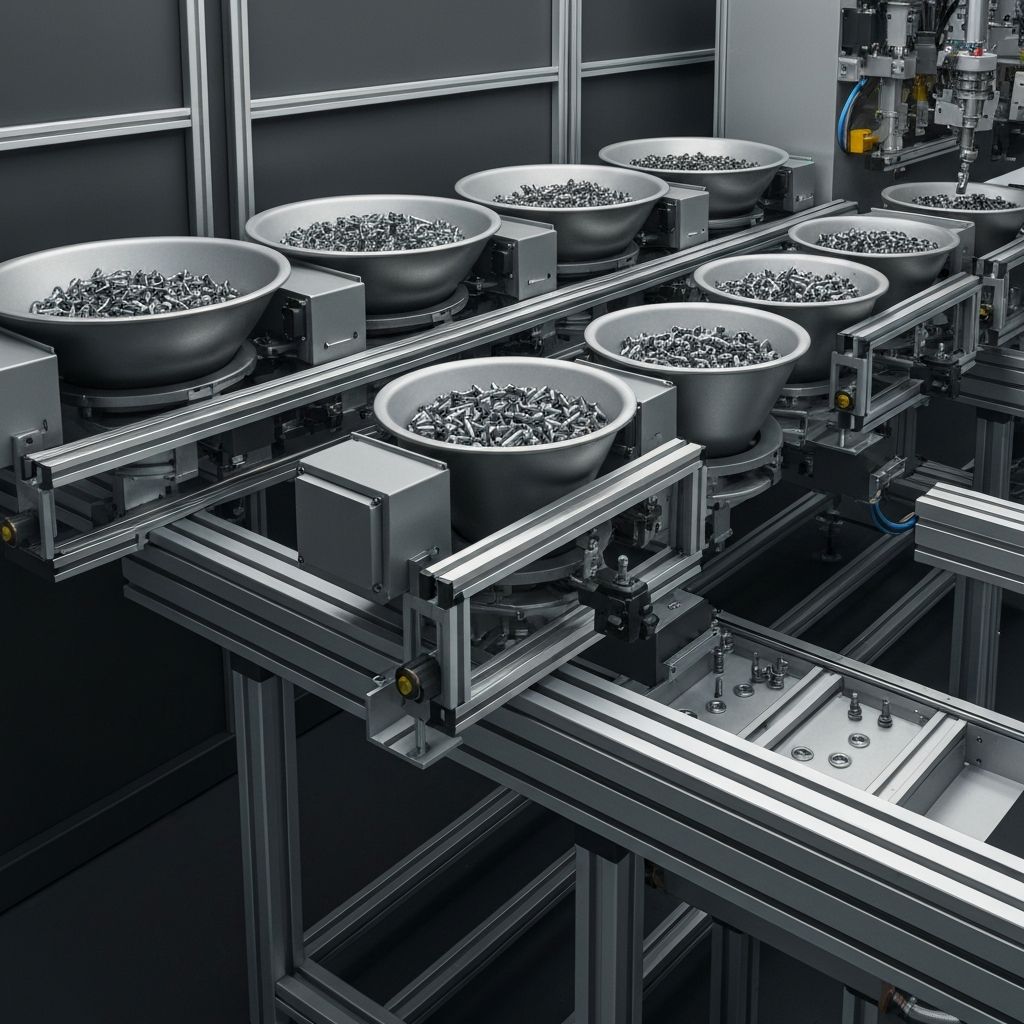

Integrated Feeding System Architecture

Hopper, feeder, track, and control modules working in coordination

2005

Founded

16+

Patents Filed

1000+

Projects Delivered

50+

Countries Served

Engineering Systems

Precision Feeding Technology

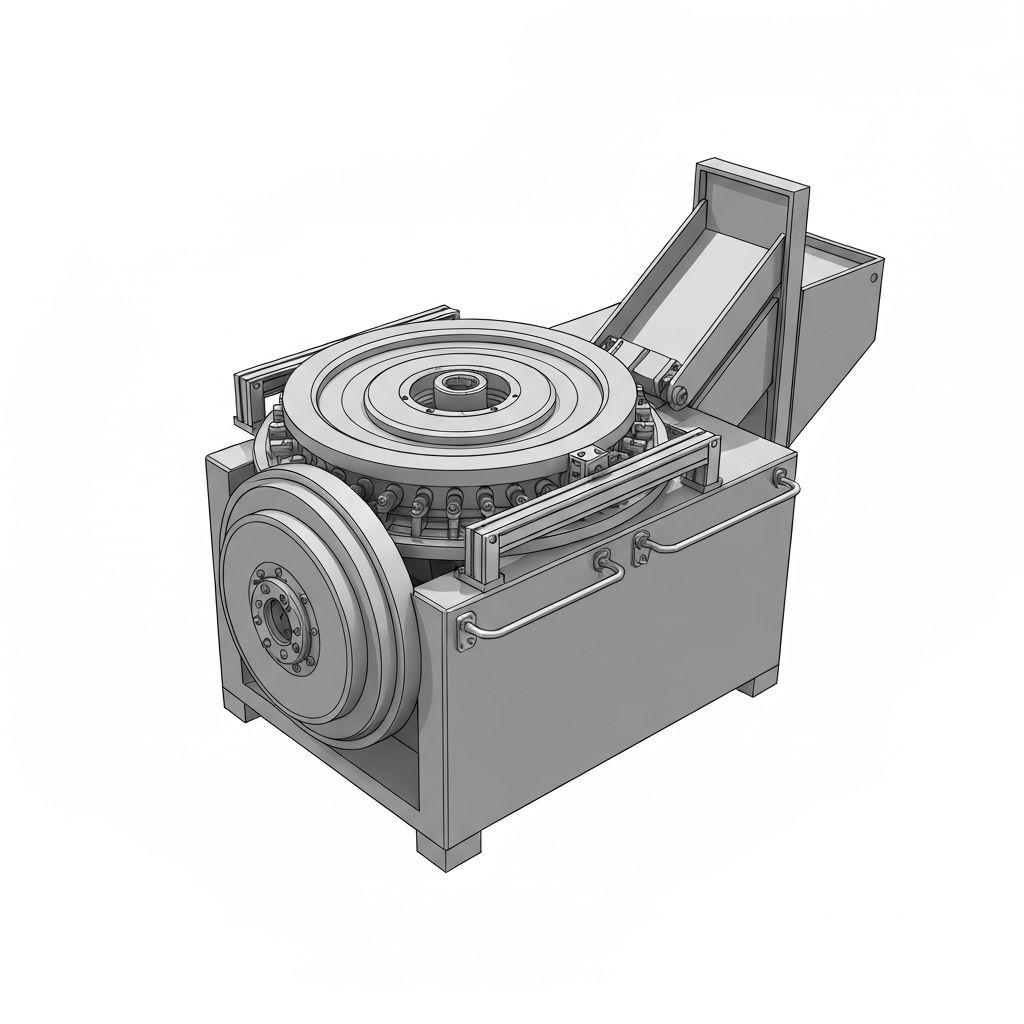

Vibratory Bowl Feeder

Custom-designed bowl feeders for precise part sorting and orientation

Handles screws, springs, metal and plastic components

Centrifugal Feeder

High-speed centrifugal feeding systems for production efficiency

Ideal for lightweight and small parts at high volumes

Step Feeder

Gentle step-by-step feeding for delicate handling requirements

Designed for fragile or complex-shaped components

Elevator Hopper

Bulk material lifting, buffering, and continuous supply

Reliable vertical transport for high-volume operations

Why HONGCHAO

Engineering Excellence Backed by Innovation

With 16 patents and nearly two decades of experience, HONGCHAO delivers feeding systems that meet the most demanding industrial requirements. Our team of engineers works closely with you to develop solutions that integrate seamlessly into your production line.

- 8 Invention Patents + 8 Utility Model Patents

- Custom non-standard automation solutions

- Strategic partnerships with leading manufacturers

- Comprehensive after-sales support

Custom Engineering

Every feeding system is designed to match your exact part geometry and production requirements.

High Throughput

Optimized bowl tooling and vibration control deliver maximum feed rates with minimal downtime.

Quality Assured

Rigorous testing and quality control ensure reliable operation and long service life.

Global Support

Technical support and spare parts network serving manufacturers worldwide.

Application Case

|AutomotiveAutomotive Fastener Feeding System

Challenge

High-speed feeding of M6 hex bolts at 800+ ppm with consistent orientation for robotic pick-and-place assembly.

Solution

Custom vibratory bowl feeder with precision tooling, linear track, sound enclosure, and elevator hopper for continuous supply.

Result

35% increase in assembly line efficiency. Noise level reduced to under 65dB with sound enclosure integration.

Industry

Automotive Manufacturing

Ready to Streamline Your Production?

Contact our engineering team today to discuss your specific feeding requirements. We will work with you to design a custom solution that optimizes your assembly process.