High-speed feeding for lightweight parts

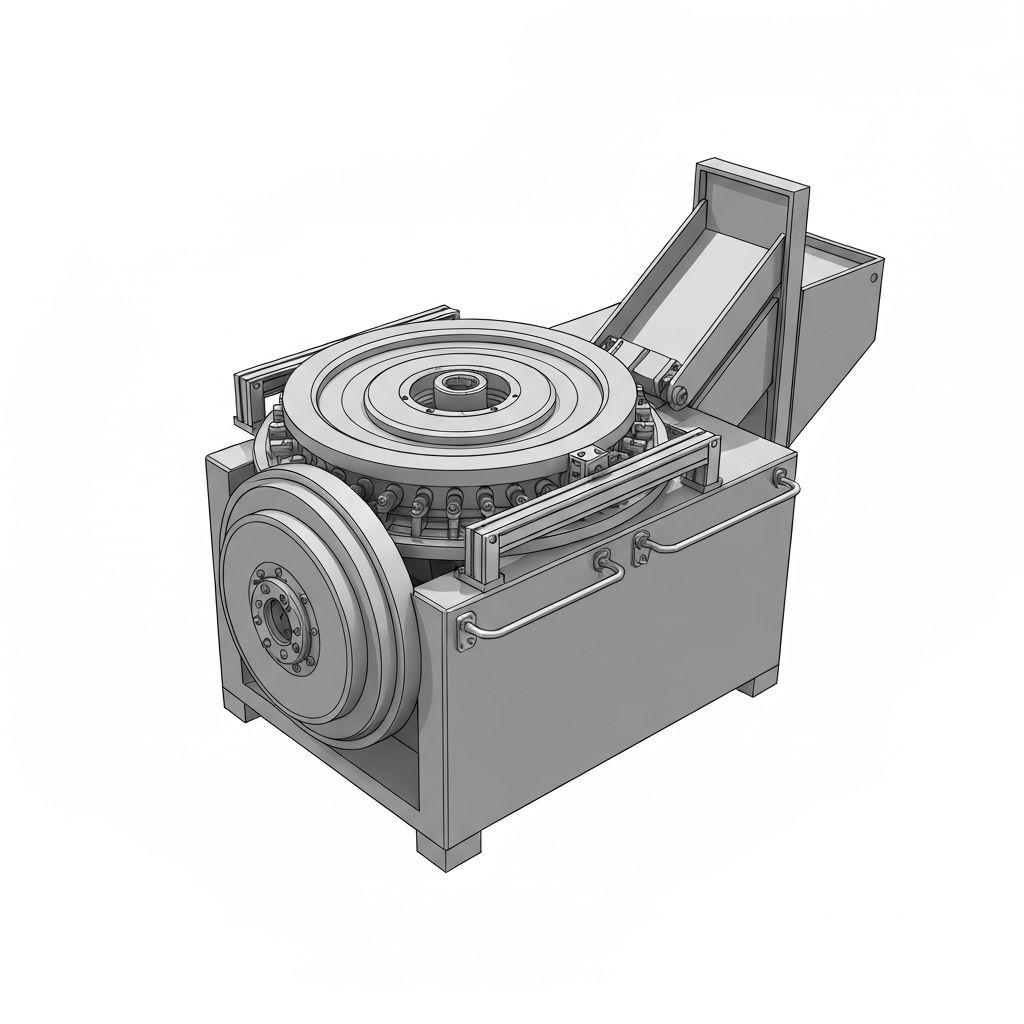

Centrifugal Feeder

High-speed centrifugal feeding systems suitable for lightweight and small parts. Ideal for high-volume production requiring rapid, consistent delivery.

Category

Centrifugal Feeder

Available Systems

Product Configurations

Standard Centrifugal Feeder

Part Type

Small lightweight parts 2-30mm

High-speed continuous output

High-Capacity Centrifugal

Part Type

Volume production applications

Extended hopper capacity

Compact Centrifugal Feeder

Part Type

Space-limited installations

Minimal footprint design

Inline Centrifugal System

Part Type

Integrated assembly lines

Direct line integration

Engineering Capabilities

Technical Expertise

High-Speed Operation

Centrifugal action delivers parts at rates exceeding traditional vibratory systems for lightweight components.

Gentle Part Handling

Smooth rotational motion minimizes part-to-part contact and reduces surface damage on delicate items.

Compact Footprint

Vertical design requires less floor space than equivalent-capacity bowl feeders.

Applications

Typical Use Cases

Our centrifugal feeder systems are deployed across diverse manufacturing operations requiring reliable, automated part feeding.

- Small fastener feeding at high speeds

- Lightweight plastic component handling

- Electronic connector pin feeding

- Small cap and closure orientation

- Pharmaceutical tablet feeding

- High-volume packaging operations

Application

Industrial Manufacturing

Technical Data

Specification Range

| Parameter | Range |

|---|---|

| Disc Diameter | 200mm – 500mm |

| Feed Rate | Up to 2000 ppm |

| Part Size | 2mm – 50mm |

| Power Supply | 220V, 50/60Hz |

| Noise Level | < 70dB |

| Control System | Variable speed with PLC interface |

Specifications vary by model and configuration. Contact engineering for application-specific requirements.

Technical FAQ

Engineering Questions

01What parts are best suited for centrifugal feeders?

Centrifugal feeders excel with small, lightweight parts under 30g including pins, caps, small fasteners, and plastic components where high speed is required.

02How does feed rate compare to bowl feeders?

Centrifugal feeders can achieve 2-3x the feed rate of equivalent bowl feeders for suitable parts due to the continuous rotational action.

03Can orientation be controlled?

Yes. Peripheral tooling and discharge tracks provide orientation control similar to bowl feeders, with parts oriented during the discharge phase.

04What maintenance is required?

Routine maintenance includes disc surface inspection, drive belt checks (if applicable), and bearing lubrication. Typical service intervals are quarterly.

Request a Custom Quotation

Provide your part details and production requirements. Our engineering team will respond with a tailored solution proposal within 48 hours.