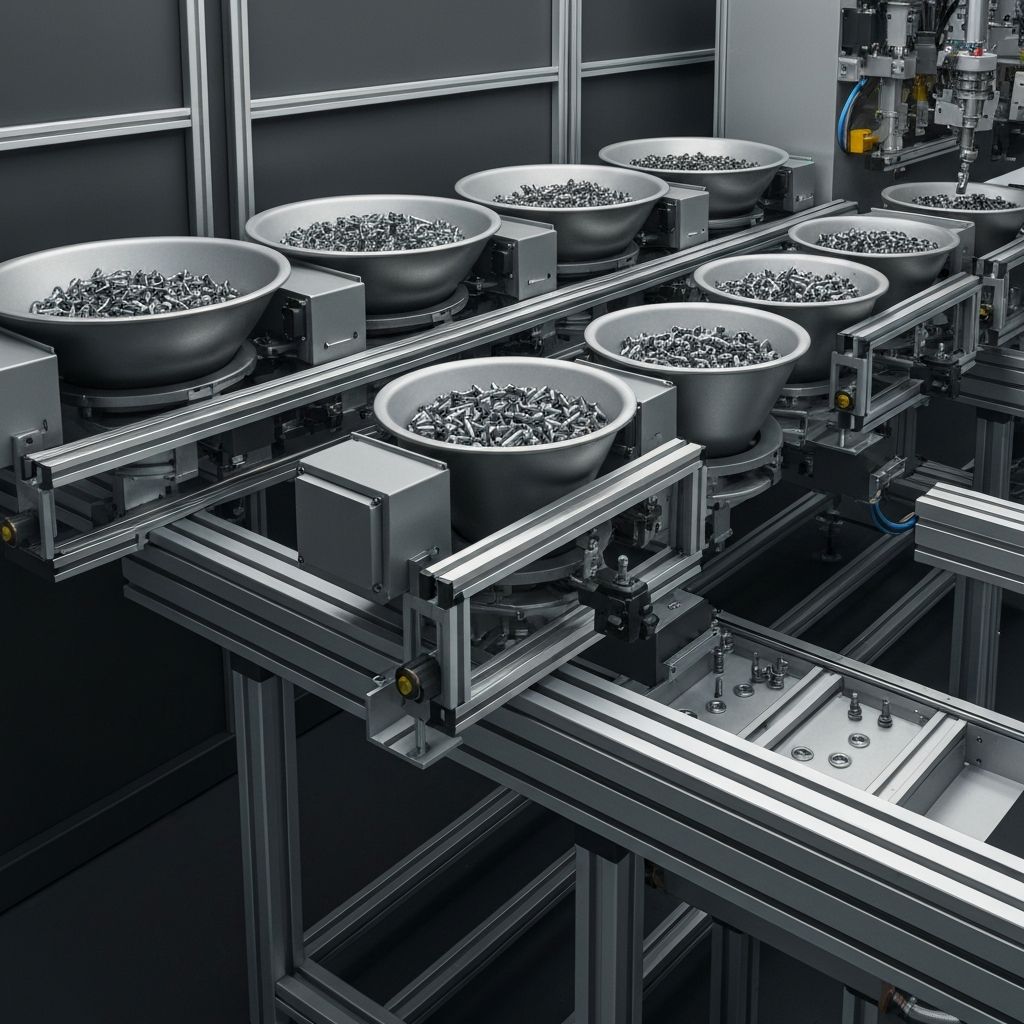

Precise part sorting and orientation systems

Vibratory Bowl Feeder

Custom-designed bowl feeders for precise part sorting and orientation. Handles screws, springs, metal components, and plastic parts with feed rates from 10 to 1000+ parts per minute.

Category

Vibratory Bowl Feeder

Available Systems

Product Configurations

Standard Bowl Feeder System

Part Type

Screws, springs, metal parts 5-80mm

Versatile configuration, proven reliability

High-Speed Bowl Feeder

Part Type

Fasteners, small components

1000+ ppm throughput capacity

Precision Bowl Feeder

Part Type

Delicate electronics, plastic parts

Gentle handling, zero-damage feeding

Multi-Track Bowl Feeder

Part Type

High-volume assembly lines

Parallel output for increased capacity

Compact Bowl Feeder

Part Type

Space-constrained applications

Reduced footprint, full functionality

Engineering Capabilities

Technical Expertise

Custom Tooling Design

Bowl geometry and track profiles engineered specifically for your part orientation requirements using 3D modeling and simulation.

System Integration

Seamless integration with hoppers, linear tracks, escapements, vision systems, and robotic pick stations.

Noise & Vibration Control

Sound enclosures achieving <75dB operation. Isolation mounts prevent vibration transmission to adjacent equipment.

Applications

Typical Use Cases

Our vibratory bowl feeder systems are deployed across diverse manufacturing operations requiring reliable, automated part feeding.

- Fastener orientation for automated assembly

- Electronics component feeding to pick-and-place

- Medical device part singulation

- Cosmetic cap and closure handling

- Automotive connector and terminal feeding

- Pharmaceutical tablet and capsule orientation

Application

Industrial Manufacturing

Technical Data

Specification Range

| Parameter | Range |

|---|---|

| Bowl Diameter | 150mm – 750mm |

| Feed Rate | 10 – 1000+ ppm |

| Part Size | 1mm – 150mm |

| Power Supply | 220V/380V, 50/60Hz |

| Noise Level | < 75dB (with enclosure) |

| Control System | Digital frequency control with PLC interface |

Specifications vary by model and configuration. Contact engineering for application-specific requirements.

Technical FAQ

Engineering Questions

01What part geometries can be handled?

Our bowl feeders handle cylindrical, rectangular, asymmetric, and complex 3D geometries. We design custom tooling based on your part CAD data to ensure reliable orientation.

02How is feed rate determined?

Feed rate depends on part size, geometry complexity, and required orientation accuracy. We provide feed rate estimates during the quotation process based on part samples or drawings.

03Can the system handle multiple part variants?

Quick-change tooling options allow switching between part variants. For high-mix applications, consider our Flexible Feeder systems with vision-guided picking.

04What is the typical lead time?

Standard systems ship in 4-6 weeks. Custom tooling development adds 2-4 weeks depending on complexity. Rush delivery available for urgent requirements.

05How is noise controlled?

Sound enclosures with acoustic dampening materials achieve <75dB operation. Bowl coatings and tuned frequencies further reduce operational noise.

06What integration options are available?

Systems include PLC interfaces (Siemens, Allen-Bradley, Mitsubishi), level sensors for hopper refill, jam detection, and output signals for downstream equipment coordination.

07What maintenance is required?

Routine maintenance includes drive base inspection (quarterly), bowl coating inspection (annual), and controller calibration verification. Average MTBF exceeds 20,000 hours.

08Can existing bowls be retrofitted?

Yes. We can retrofit new tooling to existing bowl feeders or upgrade drive bases and controls on legacy systems to improve performance.

Request a Custom Quotation

Provide your part details and production requirements. Our engineering team will respond with a tailored solution proposal within 48 hours.